Industrial Machine and Maintenance

The infrastructure of America, as we know it today, runs because of manufactured goods and advancements in technology produced by engineers, machine operators, electricians, machinists, maintenance workers, and quality control technicians.

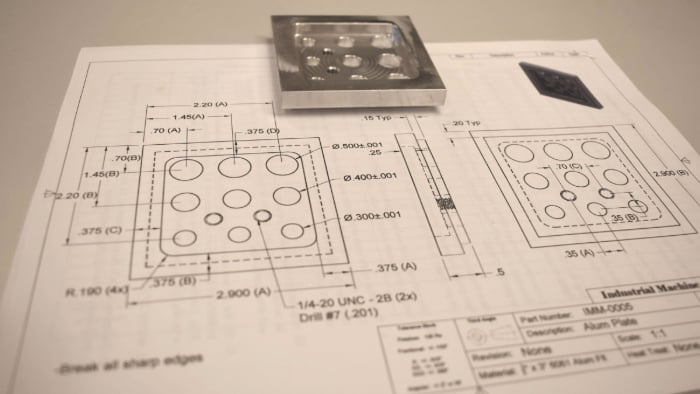

In the Industrial Machine and Maintenance program, students will dive into the process of manufacturing mechanical components, including precision measurement, blueprint reading, conventional and CNC machining processes, cutting tool and material types and selection, and Computer Aided Drafting and Design (CADD). CADD, 3D modeling, 3D printing, and tool maintenance and repair will be integrated into the content as students progress through the program. Students will spend approximately half of each training day using machining tools to complete lab projects.

The Industrial Machine and Maintenance program offers a blend of classroom instruction, lab, and live work practice. This program is fast-paced and challenging. The small class sizes at AVTEC provide students with the opportunity to experience extensive hands-on training.

The Industrial Machine and Maintenance program prepares students for entry-level employment in the manufacturing industry as an Entry Level Machinist or Entry Level Maintenance employee. During the program, students learn about and are connected with Alaskan employers in the machining industry.

Program offered in: January, August

Training Times: 8:30 am to 4:30 pm, Monday through Friday

Clock Hours: 630

Requirements

Information Technology Requirements

Students will need a laptop computer that meets the requirements of Fusion 360 Software for this training program and be able to demonstrate understanding using the following electronic equipment and functions:

- Laptop computers

- Have a basic understanding of computer graphic interfaces

Employment Requirements

- Most positions require a clean driving record with the ability to earn a valid Alaska driver’s license

- Demonstrate the ability to show up on time, rested and dressed for work

- Safety-conscious and situationally aware of surroundings

- Understand and willingly enforce industry safety standards

Program Specific Requirements

- Students must arrive on time and attend training daily (Mon-Fri 8:30 am to 4:30 pm)

- Ability to succeed in a demanding environment with rigorous academic and technical training

- Should be comfortable with constant physical activity and be able to stand for 85 percent of the training day

- Ability to stand, walk, sit, lift, push, pull, twist, turn, bend, squat, climb, kneel, crouch, crawl and reach continuously

- Required to wear safety goggles/glasses in shop areas

- Proper prescription safety glasses are recommended for students with prescription lenses

- Will supply properly fitting work clothes and steel toe or reinforced toe work boots

- May be exposed to hazardous situations that produce cuts and minor burns

- The following are minimum level of physical requirements expected to be performed:

- Lift 75 pounds

- Carry 50 pounds

- Push 100 pounds

- Pull 50 pounds

Industry Certifications

- OSHA 10

- First Aid and CPR

Graduation Achievement Levels

Level 1- Machinist Helper

Level 2- Machinist Entry-Level